The first production of beer likely happened by accident thousands of years ago. Imagine someone during those years, storing grains like barley or wheat in a container. If water got mixed with these grains, they could start to ferment because of wild yeast in the air. Fermentation is when tiny organisms called yeast turn sugars into alcohol and carbon dioxide. Someone probably tasted it and found it tasted good! That’s how the first beer was discovered.

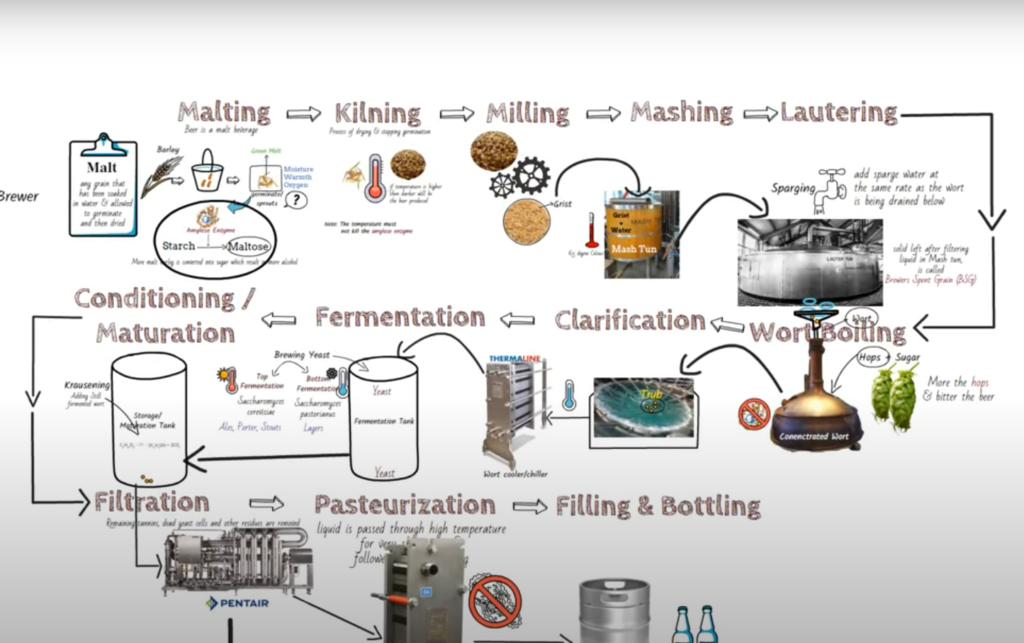

Over time, people learned to make beer on purpose. They figured out how to control the ingredients and the process to make it taste even better. And that’s how beer became one of the oldest and most loved drinks in the world! Let’s have a look down below at all the steps of how beer is made today.

How Beer Is Made?

As said earlier, beer is usually made from barley, but nowadays it is also made from other cereals such as wheat, maze, rice, oats, etc. You should know the basic information that the process of making beer is called Brewing and the person or the company that makes the beer is called Brewer and the place where the beer is made is called Brewery. Now, let’s list all the steps of the process of how beer is made:

- Malting

The term malt means any grain that has been soaked in water and allowed to germinate and then dried. Barley grains are first cleaned then soaked in water for two or three days and then excess water is drained away and allowed to germinate in germinating boxes. Malting develops the enzymes needed to convert the starches in the barley into fermentable sugars. - Germination / Sprouting

For germination to happen, moisture, warmth, and oxygen are necessary to grow this kind of shoot and rootlets. The germinated green cereals are called as green malt. So beer is made from malted grains and can be also called a malt beverage. Now let’s explain why this germination process is so important: The process of germination allows to form the amylase enzyme which helps in breaking more starch into maltose which maltose is in the form of sugar. In simple terms, more malt barley is converted into sugar the higher alcohol percentage you will get. - Kilning

At a certain time, this germination process needs to be stopped by slow heating as you don’t want to create a new plant. The process of stopping or slowing down the germination is called kilning. Temperature may vary according to the type of beer you want to make. For example, if temperature is higher then darker the beer will be the beer that you produce. Always remember that the temperature should not destroy the amylase enzyme. After kilning process you will get the dried barley grains. - Milling

Milling is the process where after kilning, the dried barley grains are crushed between rollers to produce coarse powder, which is called grist. The coarse powder is easy to dissolve in water as compared to malt grains. - Mashing

The coarse powder is then mixed with warm water in large vessel and maintained at 65 degrees Celsius for about one to two hours in Mush Tun. This creates a mash, a mixture that resembles porridge. The hot water activates the enzymes in the malt, which break down the starches into sugars. - Lautering

From the Mush Tun, the Mush is transferred to a new large vessel with a false bottom called lauter tun. Here the liquid is filtered and separated from the solid substances such as husk and other grain residue. After, is then again transferred to another vessel. Now this filtered and separated liquid is called Wort. - Wort Boiling

In this step, the wort will be transferred to a stainless steel kettle where it will be going under the process of boiling for about 2-3 hours. Hops and sugar are added at different stages of wort boiling. Hops, which are flowers from the hop plant, add bitterness, flavor, and aroma to the beer. The taste of beer depends on the type and amount of hops and sugar are added. More the hops, bitter the beer will be. Boiling also sterilizes the wort, killing any unwanted microorganisms. - Wort Clarification

The wort is either fed into the whirlpool or in the same container it was boiling. Now the hops particles and other undissolved proteins, form a cone in the middle of the container. These hops particles and undissolved proteins are called Trub which is cleared out from the wort. - Cooling

Now this clearer pure wort is cooled down to 10-20 degree Celsius. For this process they use wort cooler/chiller. The main reason to cool it down is to prevent any unwanted bacterial growth and to help clarify the beer. Also to make it ready for the fermentation process. - Fermentation

Fermentation is the most important step in how beer is made. The cooled wort is transferred to a fermentation vessel, usually a large tank or a barrel. Yeast is added to the wort, and fermentation begins. Yeast consumes the sugars in the wort, producing alcohol and carbon dioxide as byproducts. This process can take several days to weeks, depending on the type of beer being made. - Conditioning / Maturing

After fermentation, the beer is often conditioned to develop its flavor further. This can involve aging the beer into storage tanks for a period of time like several weeks or months, adding additional hops or other flavorings, or carbonating the beer. - Filtration

In the filtration process, any remaining tannins dead yeast cells, and other residues are removed after the fermentation has been completed. After filtration beer becomes clearer and beer acquires its natural texture and carbonation. - Flesh Pasteurization

In this step liquid is passed through high temperature for very short time and followed by rapid cooling. This can be done by an equipment called Plate Heat Exchanger. Pasteurization kill any spoilage microorganism and extend the shelf life of beer. It also kills any active enzyme or yeast from further fermenting the beverage. - Filling & Bottling

Now, in the final step of how beer is made, kegs or bottles are filled with the final beer product. Some brand prefer bottling just after the filtration and later those bottles or cans passed through tunnel pasteurization and stored to sell. Also some brewer or beer manufacturer don’t use the pasteurization process for genuine draft beers, which must be kept at refrigerated temperatures to preserve flavor and slow any remaining yeast activity.

One more important step that needs to be mentioned for the steps of how beer is made is that during the bottling process, some brewers also go for the carbonation process. In this step, they add co2 to make beer more fizzy. Additional of co2 is called carbonation which can be achieved by injecting the co2. If no co2 is found in the beer it is called flat beer. Although good brewers don’t add co2 as they relies on natural carbonation produced during second fermentation. Some other brewers practice bottle conditioning, adding small amount of yeast, sugar, and wort after bottling to bring on secondary fermentation inside the bottle.

Featured image from Pixabay (Free Commercial Use)

Watch The Video On Youtube For A Better Explanation Of How Beer Is Made:

Share this content:

1 comment

Very informative, thank you